WASTE WATER TREATMENT

Technologies

- ASP

- MBBR

- MBR

- SBR

- UF

- NF

- SWRO

- EDI

- Membrane Degasificatio

- API

- TPI

- CPI

- EFOP

- AOP

- UV Systems

- Ozone Systems

Applications

- Ultra Pure Water

- Process Water

- Effluent Treatment

- Zero Discharge

- Odor Removal

- Color Removal

- Oil Removal

- Refinary Waste Water

- Produced Water

- H2S Removal

- Iron Removal

- Arsenic Removal

- Cyanide Removal

- Cooling Tower Blow down Water Treatment

- Sewage Treatment

Industries We Serve

- Sugar

- Textile

- Automotive

- Cement

- Chemicals

- Electronics

- Food and Beverage

- Fertilizers

- Mining and Minerals

- Pulp and Paper

- Pharma

- Refinery and Petrochemicals

- Power

- Oil and Gas

- Municipal

- Hospital and Hotels

Freshwater is a scarce commodity; this fact is well acknowledged by one and all. People at all levels be it general public, governmental bodies, and industries understand the implications of good quality water availability in terms of quantity, cost, and wastage. As a consequence, there is a growing consensus on wastewater treatment for recycle/reuse. To achieve wastewater treatment for recycle or zero liquid discharge (zld) on an economical basis, it is not one technology that fits all, but one needs multiple technologies and careful integration of these. Each wastewater has its own nuances and to deal with these requires intimate knowledge of water chemistry and experience in the applicability of each technology.

Wastewater is the ultimate untapped resource. Shivsu Watec approach is to see waste water as an opportunity‚ not a burden. Today′ technology developments allow us to realize this vision and offer advanced wastewater treatment processes. Whether it′ ensuring that industries meet stringent discharge compliance or recovering energy from municipal sewage‚ Shivsu Watec will seek to maximize wastewater′ true hidden value.

Treatment:

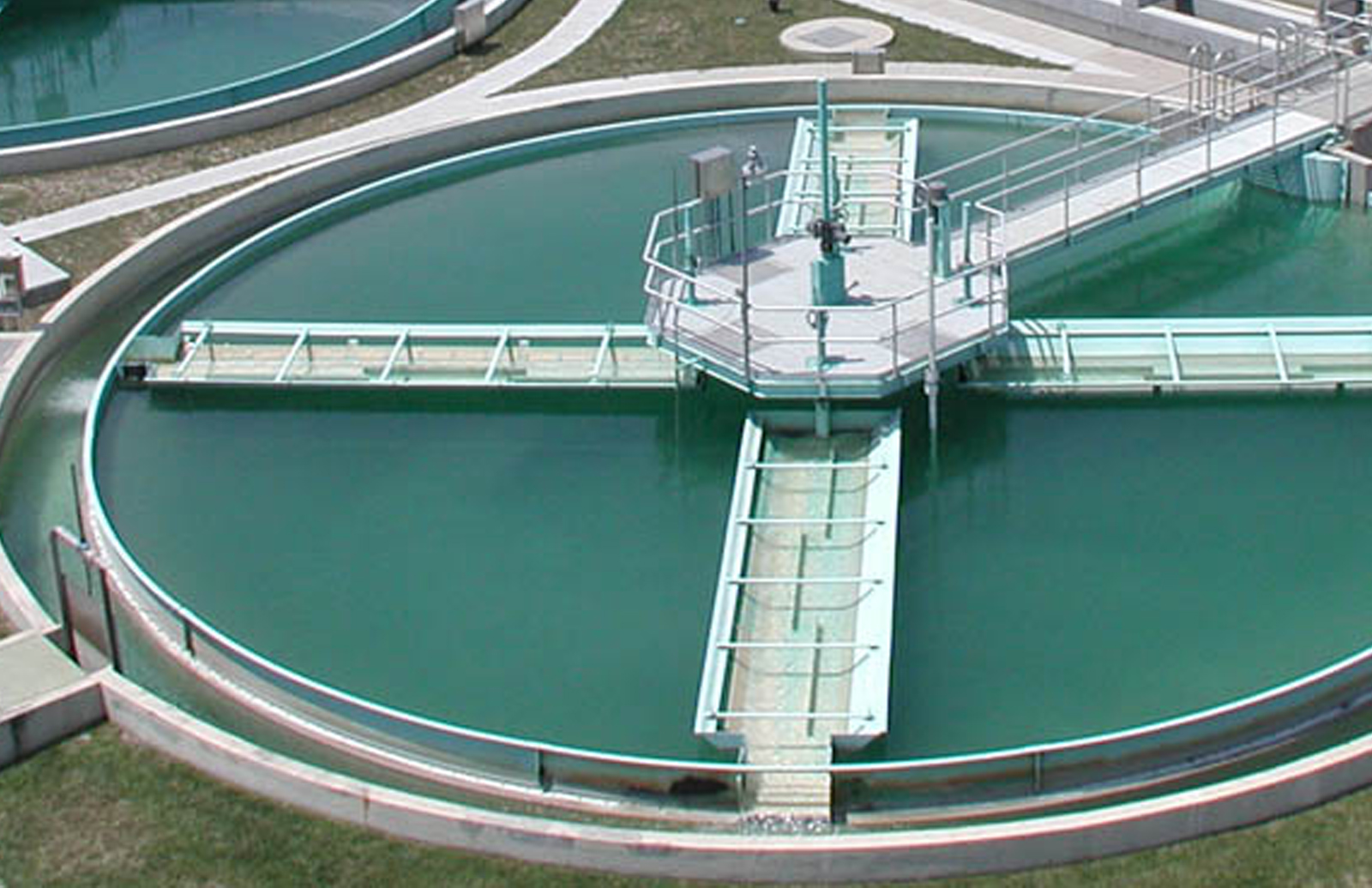

- Clarification / filtration

- Physical / chemical Treatment

- Advanced Oxidation

- Wet Air Oxidation

- Heavy Metals Removal

- Oil / water Separation

Aerobic Biological Treatment:

- Activated Sludge Process

- Integrated Fixed Film Activated Sludge (IFAS)

- Moving Bed Bioreactor (MBBR)

- Sequential Batch Reactor (SBR)

- Enhanced Membrane Bioreactor (MBR)

Anaerobic Biological Treatment:

- Upflow Anaerobic Sludge Blanket Reactor (UASB)

- High Rate Anaerobic Reactor

- Anaerobic Membrane Bioreactor

- De-ouderization

Besides technical feasibility, economic feasibility of a given treatment process for recycle is very critical and advancement in membrane processes has aided towards this cause. Shivsu Watec has successfully implemented integrated solutions for the treatment, recycle, and zld of various challenging waste streams which include municipal sewage, cooling tower blow down, flue gas desulfurization scrubbers purge stream from high sulfur based coal-fired power plants, produced water from oil and gas production industry and effluent recycle for petroleum refineries, petrochemical and chemical plants etc.