Explore Products

Filtration Equipments

Range:(1 m3/hr -100000 m3/hr )

- Clarifiers

- Pressure and Sand Filters

- Activated Carbon Filtrations

- Chemical Dosing System

- Antracite Carbon Filter

- Cartridge/bag Filter

- Micron Filters

- Micro Filters

- Iron Removal Filter

MEMBRANE BASED FILTRATION SYSTEM

Range:(1 m3/hr -100000 m3/hr )

ION EXCHANGE SYSTEM

Range:(1 m3/hr -100000 m3/hr )

STERLIZING SYSTEM

Mineral Water from your Tap Systems

Range:(0.25 m3/hr -1m3/hr )

Components

Range:(0.25 m3/hr -1m3/hr )

GLASS BOTTLING

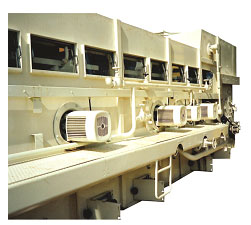

Automatic Bottle Washer - Single Soak

Automatic (Single Soak) Glass Bottle Washer

SRM 103, 106,109, 112,115, 120

- A wide range of Models

- Universal application in bottling plants

- Outputs from 60 - 350 BPM

- Efficient Cleaning & Sterilization of bottles

- Eco - Friendly

- Suitable for bottles up to 1 Litre Size

- Complete removal of Labels and Foils

- Low Maintenance Cost

Shivsu Shivsu Watec Pvt Ltd

Manufacturers of Automatic Glass Bottling Plants

In Joint Venture with

Rita Bottling

Shivsu - Rita’s SRM series Automatic Glass Bottle Washing Machines are extremely popular in a wide range of industries such as :-

- Brewery

- Dairy

- Distillery

- Juices

- Soft Drinks

- Ketchup

The larger soaking and spraying cycles ensure efficient washing of the bottles. Recycled dirty bottles are washed thoroughly without need for pre-washing. Label separators remove labels and foils completely. The machines are supplied ready for commissioning.

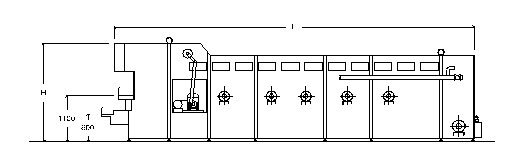

SRM Side view

Salient Feature

- Automatic loading system

- Automatic unloading system

- Auto Speed Control

- Digital Temperature Control

- Steam Condensate Equipment

- Lye Filtration

- Label Separators

- Vapour Extractor

- Water Re-Circulation

- Easy Operation

- Low Steam & Water Consumption

- Safety Clutches & Limit Switches

- Electrical Panels

- Dual Voltage Safety System

- Emergency Stop

- Fault Annunciator

- Heavy Duty Pumps & Motors

- Easy Maintenance

Treatment

| Preliminary Spray | 40° C | |

| Main Caustic Soak | 65° C | |

| Hot Caustic Lye Flushing | 65° C | |

| Hot Caustic Lye Spraying Internal | 80° C | |

| Hot Caustic Lye Spraying External | 80° C | |

| Hot Water Spray | 50° C | |

| Hot Water Spray | 40° C | |

| Fresh Water Spray | 30° C | |

| Fresh Water Spray | Ambient | |

| Drip off Zone |

- Auto Loader

- Bottle Discharge

- Pre-Spray 40°C

- Main Caustic Soak 65°C

- Label Flushing Spray

- Label Separator

- High Pressure Internal Spray

- High Pressure External Spray

- Caustic Zone 80°C

- Hot Water Zone 50°C

- Hot Water Zone 40°C

- Hot Water Zone 30°C

- Fresh Water Sprays

- Drip Off Zone

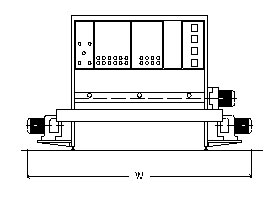

Dimensions

| Machines | SRM 103 | SRM 106 | SRM 109 | SRM 112 | SRM 115 | SRM 120 |

| Length (mm) | 5100 | 6800 | 8800 | 9600 | 10200 | 10200 |

| Width (mm) | 2900 | 2900 | 2900 | 3400 | 4350 | 5300 |

| Height (mm) | 2500 | 2500 | 2500 | 2500 | 2600 | 2600 |

| DATA | SRM 103 | SRM 106 | SRM 109 | SRM 112 | SRM 115 | SRM 120 |

| 180ml - Flat Bottles | 3600 | 6000 | 9000 | 12000 | 15000 | 21000 |

| 375ml - Flat Bottles | 3600 | 6000 | 9000 | 12000 | 15000 | 21000 |

| 650ml - Round Bottle | 3600 | 6000 | 9000 | 12000 | 15000 | 21000 |

| 750ml - Round Bottle | 3600 | 6000 | 9000 | 12000 | 15000 | 21000 |

| 250ml - Soft Drinks | 5000 | 8000 | 12000 | 15000 | 18000 | 24000 |

| 1000ml - Soft Drinks | 3000 | 4000 | 5000 | 6500 | 8000 | 10500 |

| Number of Bottles / Row | 15-20 | 15-20 | 15-20 | 20-30 | 20-30 | 20-30 |

| Number of Rows / Machine | 68 | 84 | 108 | 108 | 132 | 132 |

| Power Consumption (KW) | 15 | 24 | 30 | 36 | 46 | 60 |

| Steam (Kgs/hr) at 3.0 bar | 230 | 330 | 430 | 550 | 650 | 850 |

| Water (m3/hr) at 2.5 bar | 2.2 | 4.8 | 4.8 | 6.4 | 8 | 9 |

| Air (m3/hr) at 6.0 bar | 2 | 2 | 2 | 2 | 2.5 | 2.5 |

| Machine Weight (Tonne) | 6 | 9 | 11 | 13 | 16 | 20 |

| Service Weight (Tonne) | 12 | 16 | 20 | 24 | 30 | 35 |

Note : - Due to continuous improvements, specifications are subject to change without notice.

We also manufacture Vacuum Fillers, Tunnel Pasteurizers and Coolers, Cappers / Crowners, Premix Carbonators, Crate Washers, Cap Conveyors and Other Bottling Equipments.