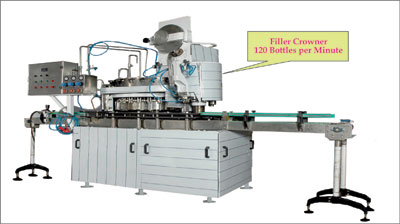

FILLING AND CROWNING MACHINE

GLASS BOTTLE FILLER

CROWNER

HIGH

SPEED CAPACITIES, SRM 224/ 236/ 240/ 260/ 280,

HIGH

SPEED CAPACITIES, SRM 224/ 236/ 240/ 260/ 280,

GERMAN TECHNOLOGY,

SUPER FLOW VALVE WITH VACUUM PRE-EVACUATION

Shivsu Canadian Clear, Manufacturers of Automatic

Glass Bottling Plants In Technical Collaboration with Rita Bottling

brings you an advanced Glass Bottle Filler Crowner machine.

Air containing 21 % oxygen is detrimental to

the stability and shelf life of beverages. The percentage of

oxygen in the bottled product has to be reduced to a minimum

since it is a risk for preservation of the bottled beverage.

The vacuum pre-evacuation system ensures removal of oxygen during

filling to give a packaged product of international standards.

Ideal for bottled beverages such as Beer, Cola, Lemonade and

Champagne. These Filling machines incorporate the latest in

filling technology for carbonated beverages. The filling valves

are designed to prevacuate the bottled before filling. This

ensures very low oxygen content in the product as per international

standards, and hence high stability and shelf life. The valves

are suitable for filling under CO2 Counter Pressure. While using

Co2 pre-stressing, one-third Air Consumption will be replaced

by Co2.

The

equipment has Cleaning in Place (CIP) facility. The equipment

has an Automatic Central Lubrication System.

The

equipment has Cleaning in Place (CIP) facility. The equipment

has an Automatic Central Lubrication System.

The machine has safety cut off switches, Automatic Splinter

Spray- off System, Height adjustment of bowl suitable for all

bottled size up to 1000ml. These filling machines are designed

for accurate level filling without beverages loss.

Note :- Due to Continuous improvements, specifications are

subject to change without notice.

We also manufacture Vacuum Fillers, Tunnel Pasteurizers and

Coolers, Bottle Washers, Premix Carbonators, Crate Washers,

Cap Conveyors and Other Bottling Equipments.

Salient Features

- Vacuum Prevuation of bottles

- Automatic Central Lubrication

| DIMENSIONS |

MACHINE |

LENGTH |

WIDTH |

HEIGHT |

SRM

224 |

2060 |

1800 |

220 |

SRM

236 |

2215 |

2040 |

2200 |

SRM

240 |

5360 |

2275 |

2760 |

SRM

260 |

5360 |

2435 |

2760 |

SRM

280 |

5360 |

3350 |

2760 |

- Low sound level

- Accurate Level Filling

- Splinter Spray off system

- High output

- Easy cleaning

- Safety cut off switches with indicators

- Cleaning in Place system (CIP)

- No Crown No run

- Electronic Speed Variator

- Low maintenance

- Easy service